Protecting Lives in Seconds

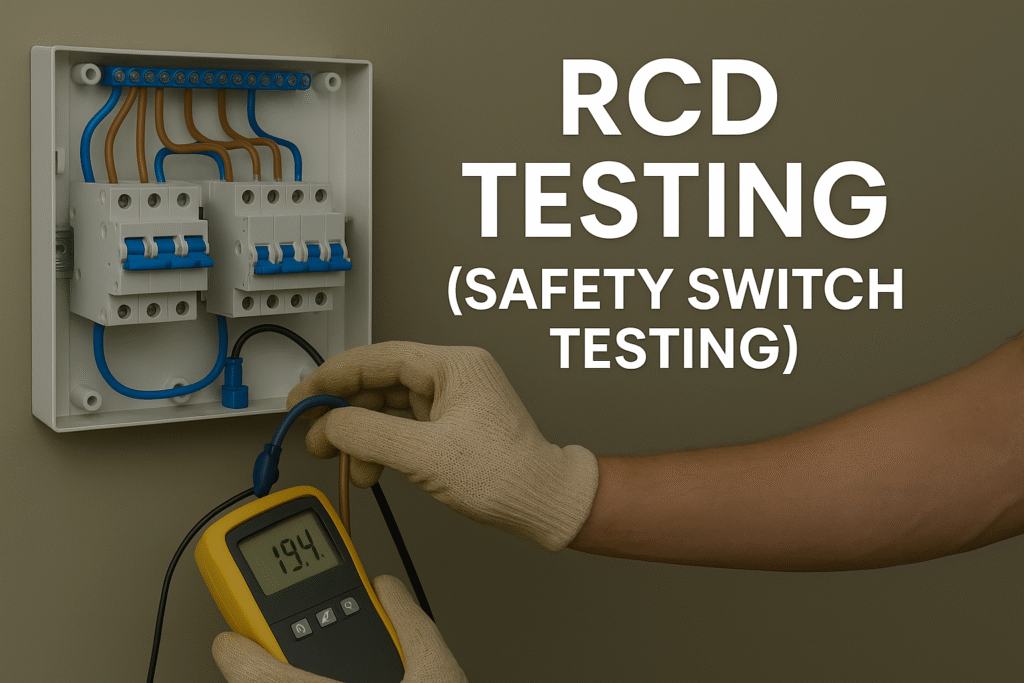

Residual Current Devices (RCDs), also known as safety switches, are life-saving devices designed to instantly cut power if an electrical fault is detected. In less than a fraction of a second, an RCD can prevent a potentially fatal electric shock. However, these devices can only save lives if they are maintained and tested regularly.

Australian safety standards require workplaces to test RCDs routinely, as outlined in AS/NZS 3760. Many businesses install RCDs and forget about them, assuming they will always work when needed. Unfortunately, like any piece of equipment, they can wear out, become faulty, or fail when tested under real fault conditions.

Why RCD Testing Is Critical:

– Protects workers, customers, and property from electrical hazards.

– Meets legal obligations for electrical safety compliance.

– Detects hidden issues before they become emergencies.

– Prevents downtime caused by electrical faults.

The Testing Process:

1. Visual Inspection: Checking wiring, connections, and switchboard integrity.

2. Simulated Faults: Technicians simulate current leaks to confirm RCDs trip within the required time frame (usually 30ms).

3. Recording Results: Test results are documented for compliance and future audits.

👉 At Evovolt Tasmania, we provide comprehensive RCD Testing services that ensure your safety switches are reliable, compliant, and ready to protect when it matters most.